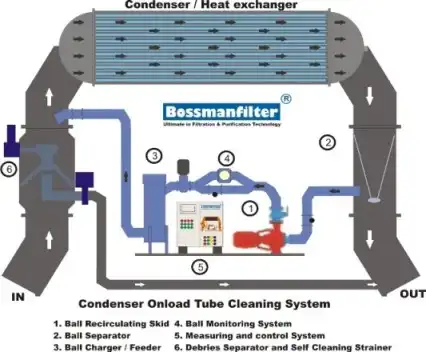

Condenser On Load Tube Cleaning System (COLTCS)

Continuous Tube Cleaning Systems (COLTCS) Condenser Tube Cleaning Systems automatically maintain the cleanliness of condenser tubes while on line, thus providing maximum heat exchange capacity.

In this systems elastomeric balls slightly larger than the tube ID are injected into the flow stream, thus wiping the surface clean of scaling contaminants within the water source. Balls are recovered on the discharge and recirculated back for additional passes or may be collected for replacement.

The Continuous Tube Cleaning Systems (CTCS) is absolutely essential in extending tube life by preventing tube fouling, scaling, under deposit corrosion and aids in prevention of MIC occurs when Micro-fouling (scaling or precipitation fouling) of condenser and heat exchanger tubes is common due to foulants in the water such as calcium carbonate, calcium sulfate, salts, and lime. Scale accumulation creates an insulation, thus greatly diminishing the heat exchange process.

Specifications

| Product Name | Condenser On Load Tube Cleaning Systems |

| Brand | Bossmanfilter |

| design operating pressure range | 10 bar @ 60 Deg.C |

| Available capacity | 2250 m3/hr to 56,500M3/hr |

| Pipe connection sizes | 24 " to 80 " (600mm to 2000mm) |

| Material | Carbon steel with internally rubber lined or epoxy coated; exterior coating as required |

| Ball strainer internals | 316L Stainless steel and other specialized materials available |

| Usage/Application: | It is widely used in Applications ◼ Power plants (fossil and nuclear) ◼Industrial pants◼ Petroleum refineries◼ Chemical plants ◼ Steel and sugar mills◼ Plants with shell and tube condensers / heat exchangers |